General Description:

NNL 690 is specifically designed for use in engines calling for medium to high ash oils (1.0% or more) and is suitable for use in most other lubricated equipment using non-E.P. oils. NNL 690 provides engines with exceptional anti-wear protection and also contains a superb detergent/dispersant package, viscosity index improvers and excellent anti-corrosion additives. NNL 690 is a balanced additive package that provides complete lubrication when used with good quality mineral based and synthetic oils.

�� Primary Benefits of NNL 690:

The primary benefit of NNL 690 is friction reduction at the boundary lubrication regime (metal to metal contact).This includes the ring zone, turbocharger and camshaft lobe areas in engines, and the pump, cylinder rods and valves in hydraulics.

Secondary Benefits of NNL 690:

Reduces ultrasonic wear noise which relates directly to component wear.

Helps prevent sludge and varnish formation.

Lowers operating temperatures by reducing friction.

Provides an improved seal around the ring zone area, improving combustion efficiency and reducing smoke opacity and blow-by.

Reduces fuel and/or electrical power consumption.

Improves filtration efficiency by reducing the generation of large wear particles.

Increases equipment availability and extends equipment life.

Product Application and Availability: NNL 690 is intended for use in internal combustion engine crankcases at 3% of the oil volume, each time the oil is changed. It is also suitable for use in automatic transmissions at an application rate of 1%, in power shift transmissions at 3%, and in circulating systems at 3% or 5%, depending on the severity of service. NNL 690 is compatible with mineral based and synthetic oils based on polyalphaolefins and diesters. At recommended application rates, it will not affect engine oil viscosity ratings or typical engine seal materials. NNL 690 is available in 1L bottles, 5L and 10L jugs, 20L pails and 205L drums. |  |

Technical Data

Typical Properties |

| Property | Method | Result |

| Appearance | | Clear, Light Amber

Liquid |

| Color | ASTM D1500 | L 2.5 |

Viscosity

@40°C (104°F)

@100°C (212°F) | ASTM D445 | 69 cSt

9 cSt |

| Viscosity Index | ASTM D2270 | 105 |

Density

@20°C (68°F) | ASTM D941 | 1.00 g/mL |

| Specific Gravity | ASTM D941 | 1.00 |

| Pour Point | ASTM D97 | -21°C (-6°F) |

| Flash Point | ASTM D92 | 195°C (383°F) |

| Base Number | ASTM D2896 | 13.3 mg KOH/g |

| Zinc and lead content | | Nil |

| Colloidal Suspension�(solid particles,PTFE, graphite,MoS2) | | None |

Test Data |

| Property | Method | Result |

| Copper Strip�Corrosion�(130oC x 2 hours) | ASTM D130 | 1b |

Rust Preventing

Characteristics

(100% NNL 690)

-Distilled water

-Synthetic sea water | ASTM D665 | Pass

Pass |

Elastomer

Compatibility

(3% in 10W-30 oil)

-Nitrile

-Neoprene

-Fluorocarbon | ASTM D4289

[modified] | Pass

Pass

Pass |

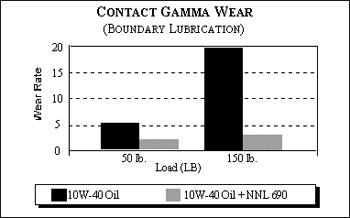

Contact Gamma Wear

@150 lb. load

10W-30 oil

with NNL 690 | | 592 teeth

77 teeth |

Special Notations

Viscosity:

A 5% application of NNL 690 in typical SAE 30 to SAE 50 weight oils results in little or no change in viscosity or viscosity index of the oil.

Pour Point:

NNL 690 is formulated to have a negligible effect on the pour point of typical engine oils.

Alkaline Reserve:

Power Up NNL 690 is blended with an acid scavenger to neutralize blow-by gases and acidic oil degradation products. The addition of 3% NNL 690 will increase the base number of engine oils by about 0.5 mg KOH/g.

Application:

NNL 690 is intended for use in engine crankcases at 3% of the oil volume, each time the oil is changed. It can also be used in automatic transmissions at an application rate of 1%, power shift transmissions at 3% and in circulating systems at 3% to 5%, depending upon operation conditions. NNL 690 is compatible with all mineral oils and polyalphaolefin and diester based synthetic oils. NNL 690 is not recommended for use with water based fluids, phosphate esters or polyglycol fluids.

Power Up NNL 690 is a unique boundary lubricant which is specifically formulated to solve many of today's tribological problems in the boundary lubrication regime. NNL 690 works by forming a wear reducing, protective film which is capable of withstanding extreme pressures. NNL 690 provides critical engine parts, such as the ring zone, cam lobes and turbocharger, with boundary lubrication protection far exceeding that of conventional oils. NNL 690 is a carefully balanced, complete additive package which contains anti-wear and extreme pressure additives, detergent/dispersants, viscosity index improvers, corrosion inhibitors and acid neutralizers.

Boundary lubrication protection:

In independent Contact Gamma wear tests, NNL 690 significantly reduced the amount of wear generated when an engine oil alone was used. The results are provided graphically in Figure 1 below. Calculated estimates based on wear reduction (up to 86.9%) suggest that the use of NNL 690 can extend equipment life over 7 times by reducing wear up to 86.9%.

Fig. 1 - Contact Gamma Wear Test Results |

|

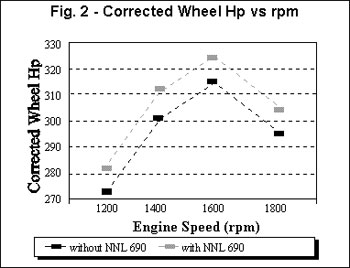

Diesel Engine Field Test

A series of dynamometer and ultrasonic noise tests were carried out by an independent consultant to determine the effect of Power Up NNL 690 on a diesel highway tractor engine. The application of 3% NNL 690 increased the horsepower and torque, while reducing fuel consumption, ultrasonic wear noise and emissions. Some of the computer controlled and corrected dynamometer results are given in Figures 2 and 3.